Urethane foam is an extremely versatile and commonly used type of foam. Urethane foam is a polyurethane-based substance that can be stiff or flexible and is utilized in various industries, including construction, furniture, automotive, and medical. Read More…

The applications for foam fabricating are only limited by one’s imagination; that is our slogan at American Excelsior. We are a foam supplier who offers many different foam cushions & foam padding for over a dozen industries.

Since 1992, Flextech has delivered innovative, custom engineered foam solutions. We combine our engineering and design services with our unique foam lamination, fabrication, and thermoforming capabilities, to provide quality foam components to a diverse customer base. Our customers include OEM’s in the medical, industrial, military, aerospace and consumer products markets. We invite you to...

Deluxe Packaging works hard to always create cost-effective solutions and services for our clients better than anyone else. We offer a full array of high quality products, including polyurethane foam, polystyrene foam, and polyethylene foam. Our products are customizable to match a product’s fragility and size. Deluxe Packaging is your complete packaging solution provider for all of your...

Here at Thrust Industries we provide die cut foam that comes in a variety of shapes and configurations. We die cut foam from a number of materials including: urethane, PVC, polyester, neoprene, ether, cellular, volara, and much more.

More Urethane Foam Companies

What is Urethane Foam?

Urethane foam, also known as polyurethane foam, is a highly versatile material commonly found in a wide range of industries due to its unique combination of comfort, support, and resilience. Urethane foam is extensively used in hospital equipment—including surgical scrubbers, x-ray positioning pads, and specialty medical cushions—for its hypoallergenic properties, light weight, and ability to be fabricated in custom shapes. Additionally, it serves critical roles in acoustic insulation and thermal insulation, protecting spaces from unwanted noise and temperature fluctuations. In packaging, urethane foam is valued for its shock absorption and protective qualities, ensuring safe transportation of delicate goods. The automotive industry utilizes urethane foam for interior cushioning, headliners, armrests, and even in sound dampening panels.

Depending on the microscopic structure of urethane foam, it’s classified as either open cell foam or closed cell foam. Open cell urethane foam features interconnected pores that make the material soft, flexible, and highly absorbent—ideal for sponges, soundproofing, and medical pads. In contrast, closed cell foam has sealed, discrete cells that render it denser, more rigid, and resistant to moisture, making it suitable for structural support, insulation panels, and water-resistant applications.

How Urethane Foam is Made

Urethane foam manufacturing is a sophisticated chemical process involving the reaction of diisocyanates and polyols—chemical compounds derived primarily from crude oil, although plant-based polyols are also increasingly used for eco-friendly options. The introduction of blowing agents, surfactants, pigments, and other additives allows manufacturers to customize the foam’s density, resilience, and color. This versatility is one reason why urethane foam is favored for both standard and custom applications.

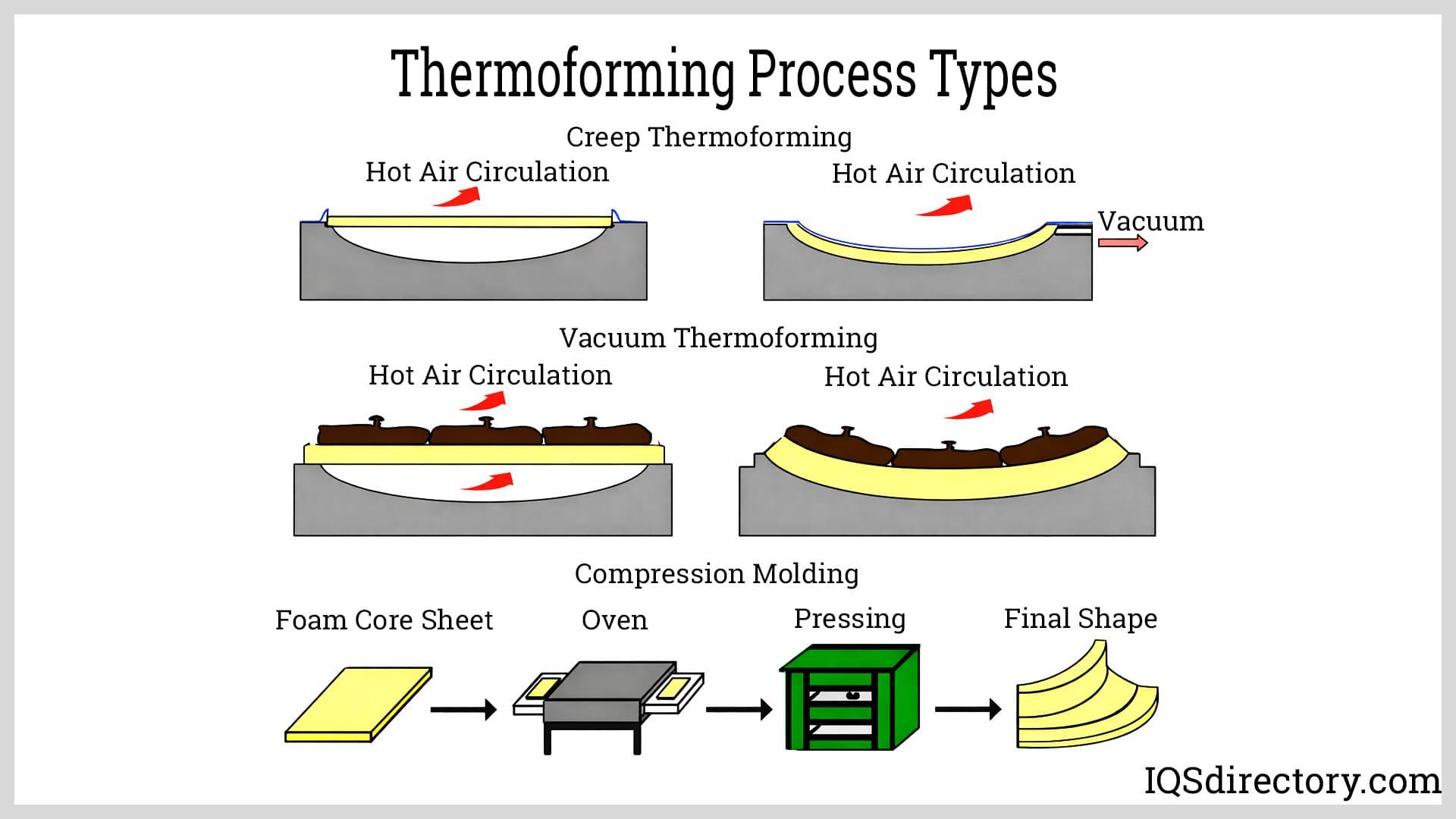

During production, the isocyanates and polyols are thoroughly mixed in precise proportions, initiating a polymerization reaction that produces a continuous block of flexible or rigid foam. This block is poured onto a moving conveyor belt, where it expands and solidifies. Modern CNC foam cutting technology and advanced fabrication methods—including hot wire, laser, and water jet cutting—enable bulk foam blocks to be cut into exact, consistent shapes for use in mattresses, furniture, automotive parts, and medical equipment. For highly specific requirements, urethane foam can be molded into complex 3D shapes, accommodating ergonomic contours for seating and bedding.

After curing and cooling—typically for up to 24 hours—urethane foam is ready for further processing or shipment. Manufacturers frequently adhere multiple foam components together or laminate them with fabrics and films to enhance performance in specialized applications, such as flame retardancy, antimicrobial resistance, or added durability for outdoor use.

Looking for Custom Urethane Foam Solutions?

Are you seeking custom-shaped foam inserts, tailored densities, or specialized foam fabrication for your project? Explore foam fabrication services to match your precise requirements—whether you're in need of protective packaging, medical components, or innovative product design.

Properties of Urethane Foam

Urethane foam exhibits a diverse set of physical properties that make it a staple material in many industries. Whether you’re evaluating foam for comfort, durability, or technical performance, understanding these properties is crucial for selecting the right material for your application.

- Compression Set: This measures the reduction in thickness after the foam is compressed under controlled conditions. A low compression set indicates that the foam will retain its shape and cushioning properties over time—essential for seating and bedding.

- Tensile Strength: Refers to the maximum force required to break a foam specimen of a given cross-sectional area. Higher tensile strength enhances durability, making the foam suitable for high-stress environments such as automotive interiors or athletic padding.

- Elongation at Break: The extent to which the foam can stretch before breaking, expressed as a percentage of its original length. This property is critical for applications requiring flexibility and resilience, like orthopedic supports or athletic equipment.

- Tear Resistance: The force needed to initiate and propagate a tear in the foam. High tear resistance is vital for products exposed to mechanical stress or repetitive use, such as packaging inserts and protective cases.

- Static Fatigue (Static Durability): Measures the foam’s ability to maintain its load-bearing capacity and thickness after prolonged static loading. Low static fatigue is key for mattresses, cushions, and other products subjected to long-term pressure.

- Density and Firmness: Foam density (measured in pounds per cubic foot or kilograms per cubic meter) directly impacts firmness, support, and durability. Higher-density foams tend to offer greater longevity and resistance to deformation.

- Thermal Insulation: Urethane foam’s cellular structure traps air, providing excellent insulation against heat loss or gain—crucial for construction, refrigeration, and HVAC applications.

- Acoustic Performance: Open cell urethane foams are often used for sound absorption in studios, offices, and transportation to reduce echo and control noise pollution.

- Chemical and Moisture Resistance: Closed cell urethane foams resist water absorption and many chemicals, making them suitable for marine environments, medical devices, and industrial gaskets.

- Flame Retardancy: Specialty urethane foams can be formulated to meet stringent fire safety standards for use in public spaces, vehicles, and aircraft.

How Do You Choose the Right Foam Properties?

Not sure which properties matter most for your application? Contact a foam specialist to discuss your performance requirements—such as compression strength, density, or fire resistance—and receive expert guidance on material selection.

Applications of Urethane Foam

The adaptability of urethane foam makes it a preferred choice in countless industries. Its customizable characteristics allow it to address a broad spectrum of needs, from everyday comfort to technical problem-solving.

- Furniture and Bedding: Urethane foam is the cornerstone of modern mattresses, sofas, and chairs, providing the ideal balance of support and softness. Advanced foams are used in memory foam mattresses, toppers, and ergonomic seating.

- Automotive Interiors: Used for seat cushions, headrests, armrests, and noise-reducing panels. Its lightweight and energy-absorbing properties enhance passenger comfort and vehicle safety.

- Medical and Healthcare: Urethane foam’s hypoallergenic and antimicrobial formulations make it suitable for surgical pads, wound care dressings, prosthetics, and medical positioning devices.

- Packaging and Shipping: Custom-cut urethane foam inserts protect electronics, medical equipment, and fragile goods during transit. Its shock-absorbing characteristics reduce damage risk and enhance product presentation.

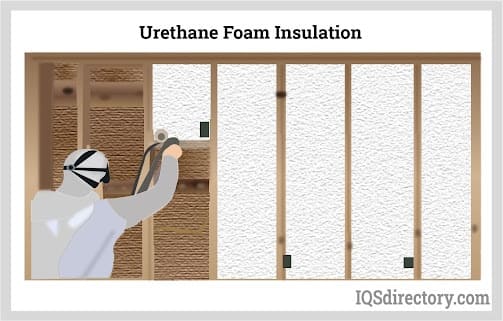

- Construction and Insulation: Urethane foam is widely used for spray foam insulation, wall panels, roofing systems, and air sealing. It offers high R-values, air tightness, and moisture resistance, contributing to energy efficiency and sustainable building practices.

- Soundproofing: Open cell urethane foam panels and tiles are installed in studios, offices, and homes to absorb sound, reduce echo, and enhance acoustic quality.

- Sports and Recreation: Athletic pads, yoga mats, helmet liners, and protective gear all benefit from the shock absorption and resilience of urethane foam.

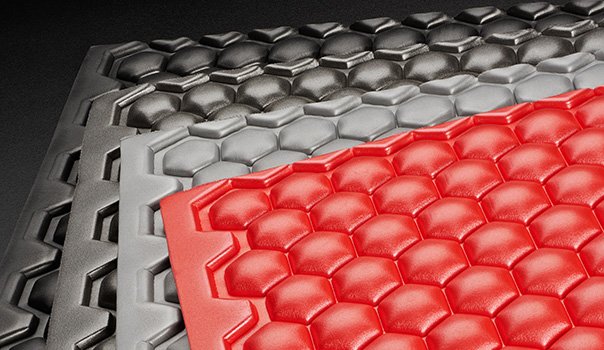

- Industrial Applications: Urethane foam is fabricated for gaskets, seals, vibration dampening, filtration, and custom fixtures across multiple manufacturing sectors.

- Marine and Aerospace: Closed cell foams provide buoyancy, flotation, and lightweight structural support in boats and aircraft.

- Consumer Products: From kitchen sponges to cleaning pads, toys, and pet beds, urethane foam is found in countless household items.

-

In building insulation, spray urethane foam expands to fill gaps in attic roofs, walls, and crawl spaces, eliminating air leaks and improving energy efficiency. Its outstanding thermal resistance makes it a top choice for contractors and builders seeking sustainable, high-performance insulation.

Want to See How Urethane Foam Can Solve Your Challenge?

Curious about how urethane foam can be tailored for your industry or product line? Explore industry-specific use cases or request a custom quote for your unique application.

Benefits of Urethane Foam

The widespread use of urethane foam is driven by its many advantages, which provide both immediate and long-term value for manufacturers and end users alike.

- Design Flexibility: Urethane foam can be engineered in a vast range of densities, thicknesses, and firmness levels to suit virtually any application—from plush mattress toppers to rigid structural panels.

- Lightweight Strength: Even high-density foams offer excellent strength-to-weight ratios, reducing shipping costs and making installation easier.

- Enhanced Comfort: Its cushioning properties provide ergonomic support in seating, bedding, and wearable products, reducing fatigue and improving user experience.

- Durability: Urethane foam’s resistance to compression set, tearing, and fatigue ensures long service life, even under repeated use.

- Thermal and Acoustic Insulation: Reduces energy bills and noise pollution, adding value in both residential and commercial settings.

- Moisture and Chemical Resistance: Closed cell varieties are impervious to water and many chemicals, ideal for humid or harsh environments.

- Health and Safety: Options for hypoallergenic, antimicrobial, and flame-retardant formulations meet strict regulatory requirements for public spaces, healthcare, and transportation.

- Cost-Effectiveness: Urethane foam offers affordable material and processing costs, especially in high-volume manufacturing.

- Eco-Friendly Options: Plant-based polyols and recyclable foam varieties are available for sustainability-focused projects.

Is Urethane Foam Right for Your Product?

Trying to decide if urethane foam is the best material for your next project? Compare its properties and benefits with other foam types or consult with an expert by contacting us for personalized advice.

Choosing the Proper Urethane Foam Manufacturer

Selecting a urethane foam supplier or manufacturer can have a significant impact on your project’s timeline, cost, and product performance. When you’re ready to purchase urethane foam or custom foam components, it’s essential to evaluate potential partners based on key factors:

- Industry Experience: Does the manufacturer have a proven track record in your target industry, such as automotive, medical, construction, or packaging?

- Customization Capabilities: Can the supplier fabricate foam to your required dimensions, densities, and shapes? Look for advanced cutting and molding technologies.

- Quality Control: Is the foam tested for properties like compression set, density, and fire resistance? Certifications such as ISO 9001, CertiPUR-US, or UL ratings can signify high standards.

- Lead Times and Volume Capacity: Can the supplier handle your order size and meet your project deadlines?

- Value-Added Services: Do they offer design support, prototyping, assembly, or logistics management to streamline your supply chain?

- Sustainability: Are eco-friendly or recyclable foams available for green building, packaging, or product initiatives?

- Customer Service: Does the manufacturer provide responsive communication, technical expertise, and support throughout the buying process?

To ensure the most productive outcome when purchasing urethane foam from a urethane manufacturer, it is important to compare several companies using our comprehensive directory of urethane foam manufacturers. Each urethane foam manufacturer has a business profile page illustrating their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each urethane foam business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple urethane foam companies with the same form.

Ready to Find the Best Urethane Foam Supplier?

Compare top urethane foam manufacturers to request quotes, review capabilities, and select the ideal partner for your next project.

Frequently Asked Questions About Urethane Foam

- What is the difference between polyurethane foam and memory foam?

Memory foam is a type of polyurethane foam with added viscoelastic properties, making it softer and more conforming for bedding and comfort applications. - How long does urethane foam last?

High-quality urethane foam can last 8–15 years or more, depending on usage, density, and environmental exposure. - Is urethane foam environmentally friendly?

Traditional urethane foam is petroleum-based, but many manufacturers now offer plant-based, low-VOC, and recyclable options for eco-conscious buyers. - Can urethane foam be recycled?

Some types of urethane foam can be mechanically or chemically recycled, reused in carpet padding, or processed for energy recovery. - What factors affect urethane foam price?

Pricing depends on foam density, thickness, processing complexity, order volume, and customization requirements. - How do I specify the right foam for my application?

Consult with a foam fabricator or supplier, providing details about load requirements, environmental exposure, certifications needed, and intended use.

Have More Questions?

Ask our foam experts or request a custom quote for your project today.

Die Cutting

Die Cutting Foam Fab

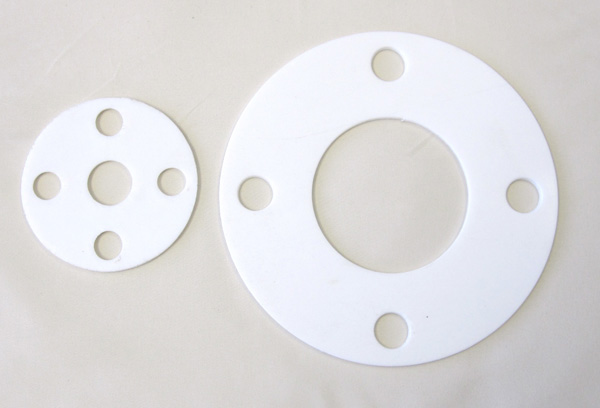

Foam Fab Gaskets

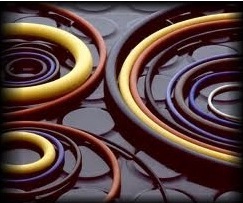

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services