Foam is defined as a substance that consists of countless little air bubbles trapped in a solid or liquid state. Foam fabricating is the process of converting polymer foam, a material that is versatile and lightweight. In general, during foam fabrication, foam fabricators melt the material down, froth it up, then cool it. This process fills the material with little bubbles and gives it its sponge-like appearance. Read More…

The applications for foam fabricating are only limited by one’s imagination; that is our slogan at American Excelsior. We are a foam supplier who offers many different foam cushions & foam padding for over a dozen industries.

Since 1992, Flextech has delivered innovative, custom engineered foam solutions. We combine our engineering and design services with our unique foam lamination, fabrication, and thermoforming capabilities, to provide quality foam components to a diverse customer base. Our customers include OEM’s in the medical, industrial, military, aerospace and consumer products markets. We invite you to...

Deluxe Packaging works hard to always create cost-effective solutions and services for our clients better than anyone else. We offer a full array of high quality products, including polyurethane foam, polystyrene foam, and polyethylene foam. Our products are customizable to match a product’s fragility and size. Deluxe Packaging is your complete packaging solution provider for all of your...

Here at Thrust Industries we provide die cut foam that comes in a variety of shapes and configurations. We die cut foam from a number of materials including: urethane, PVC, polyester, neoprene, ether, cellular, volara, and much more.

More Foam Fabricating Companies

Foam fabricating encompasses the types of foam and the diverse range of products and applications derived from them. Whether you are seeking solutions for industrial, commercial, or residential needs, foam fabrication services play a critical role in delivering customized materials that meet exact specifications for performance, durability, and efficiency.

Foam Applications

Foam fabrication is an advanced manufacturing process that produces highly specialized materials and products tailored to meet a myriad of functional requirements. These products serve critical roles in insulation, sealing, liquid absorption, vibration dampening, cushioning, protection, soundproofing, filtration, and structural support.

The versatility of fabricated foam makes it indispensable across diverse industries. In the furniture sector, it provides essential comfort and durability. In electronics, it offers precise protective packaging and thermal management. The automotive industry benefits from its impact absorption and noise reduction properties. Construction applications include thermal insulation and soundproofing solutions. Healthcare relies on foam for medical cushioning and support devices. In households, it finds use in various everyday products, while in acoustics, it enhances sound quality by reducing noise and reverberation.

Moreover, fabricated foam plays a vital role in filtration systems, ensuring clean air and fluids. Its utility extends to demanding environments such as oil rigs, satellites, and weather balloons, where its unique properties meet stringent performance criteria.

Are you searching for custom foam packaging to protect sensitive electronics during shipping? Or do you need acoustic foam panels for professional soundproofing and noise reduction? Foam fabricators can design and manufacture solutions that perfectly fit your application. Companies in the foam fabrication industry specialize in developing foam inserts, medical foam pads, sealing gaskets, environmental barriers, filtration media, and energy-absorbing components for a variety of sectors.

- Automotive Industry: Foam is used for seat cushioning, NVH (noise, vibration, and harshness) insulation, door panel padding, and crash protection components.

- Construction and Building: Insulating foam boards, expansion joint fillers, soundproofing underlayments, and weatherstripping foam seals.

- Medical and Healthcare: Patient positioning pads, surgical supports, wound care dressings, and custom orthotic inserts.

- Packaging and Shipping: Die-cut foam inserts, custom foam end caps, protective case liners, and anti-static foam packaging for electronics.

- Consumer Products: Memory foam mattresses, furniture cushions, ergonomic pillows, and sports padding.

- Electronics: EMI/RFI shielding foam, thermal interface foam pads, and sensitive device packaging solutions.

- Acoustics and Studio: Wedge foam, pyramid foam, bass traps, and sound barrier foam panels for recording studios and theaters.

Wondering how foam fabrication can address your specific application? Contact a foam manufacturer for guidance on material selection, design customization, and cost-effective production methods that enhance your project’s performance and longevity.

Types of Foam

Foam fabricating services produce various foam types for diverse applications. Open-cell foams are flexible and allow air flow through their interconnected cells, whereas closed-cell foams have dense, isolated cells that block air flow. Acoustic foams, either attenuated or non-attenuated, are designed to absorb or shape sound, respectively. Packaging foams are specialized for product packaging and shipping, ensuring the safe transport of items.

Bonded foams are created by gluing shredded foam or foam particles together, typically used for carpet cushioning. Flexible foams, known for their resilience, are commonly found in bedding and furniture. Adhesive-backed foams, which hold foam padding in place and maintain uniform pressure, are particularly popular in medical applications. Cushion foams provide essential support in furniture and athletic gear.

Molded foam retains its shape, compressing under pressure and returning to its original form when the pressure is removed. Rigid foam, characterized by its moisture and heat resistance, is a type of closed-cell foam ideal for various demanding applications.

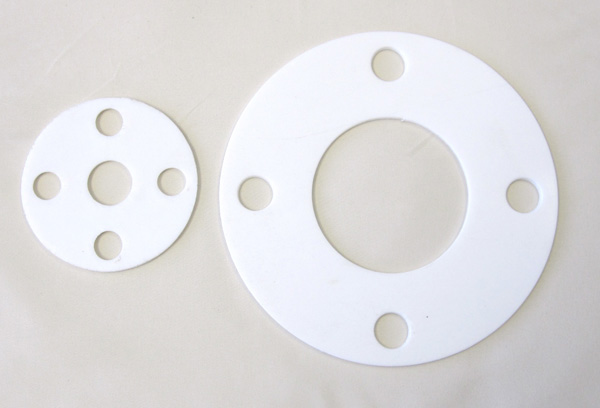

Products made from polyurethane foam include insulated containers, flexible seating, protective padding, insulation foam, EKG pads, x-ray positioning pads, and surgical scrubbers. Polyethylene foam products are used for bracing and cushioning in the handling, packaging, and shipping of items such as clothing, food, sporting goods, signs, furniture, and computer parts. Other foam fabricated products encompass gaskets, pillar stuffers, couch cushions, slipper padding, sponges, mats, filters, orthopedic inserts, NVH seals, AC unit filters, memory foam mattresses, and pillows.

When comparing open-cell foam vs. closed-cell foam, consider the end-use requirements. Open-cell foam is lightweight, flexible, and highly breathable, making it suitable for cushions, soundproofing, and filtration. Closed-cell foam is denser, moisture-resistant, and more durable, making it ideal for insulation, flotation, and structural applications.

Curious which foam type is best for your product design? Explore our directory of foam fabricators to find expert guidance tailored to your industry and application.

History of Foam

People began fabricating foam products between the 1920s and 1930s following the development of latex foam. The initial methods for creating polymeric foams were the Talalay and Dunlop processes. The Talalay process, created in the 1930s by Joseph, Leon, and Anselm Talalay, led Joseph to establish Vita Talalay, a company operating in the Netherlands, US, UK, and Canada. The Dunlop process was patented by the Dunlop Rubber Company in 1929.

These advancements allowed companies worldwide to develop rubber foams for diverse applications. The mid-20th century saw rapid growth in foam fabrication, driven by WWII demands and continuous scientific discoveries in rubber materials and chemicals. In 1947, Dow Chemical researchers invented Styrofoam, or foamed polystyrene.

Today, foam fabricators continue to innovate, including the creation of nanocellular polymer foams. A key focus is sustainability; to minimize environmental impact, fabricators now prioritize reusing and recycling foam scrap instead of burning it.

Looking for information on the environmental impact of foam manufacturing? Many modern foam fabricators offer eco-friendly foam solutions by using recycled content and sustainable manufacturing practices, ensuring compliance with green building standards and environmental regulations.

Foam Materials and Design

Fabricators utilize various materials to produce foam, including plastics, rubbers, and low-density elastomers such as polyurethane, polyethylene, cross-linked polyethylene, polyether, PVC, and expanded polystyrene (ESP). Plastic foams, characterized by tiny, evenly distributed gas bubbles, are lightweight and possess a high strength-to-weight ratio. Among these materials, polyurethane foam is the most widely used due to its durability and ability to biodegrade in sunlight. Polyethylene, another common material, is favored for its flexibility, shock absorption, vibration dampening, and insulation properties. It is primarily extruded as an expanded, closed-cell plastic foam for protective applications. A specific type of polyethylene foam, known as Ethafoam, is particularly noted for its exceptional shock absorption capabilities.

Cross-linked polyethylene (XLPE) is known for its chemical and physical resistance. As a foam, it is smooth, thick, and extremely fine-celled. Polyether foam is a cost-effective closed-cell foam with adequate acoustic and packaging properties. PVC, or vinyl, is self-extinguishing, moisture-resistant, and rot-proof, creating a soft, pliable, and closed-cell foam that bonds well with adhesives. It is commonly used in gaskets to prevent water transmission. Expanded polystyrene (EPS) is versatile, used in applications such as padding in slippers, insulation foam, oil rigs, filter foam in AC units, satellites, and weather balloons.

When preparing to fabricate a foam product, fabricators evaluate several factors, including the type of material, fabrication processes, product shape, thickness, and standard requirements. A key decision involves choosing between closed-cell and open-cell foam.

Closed-cell foams consist of sealed and separate cells, giving them high compressive strength and density. The cells expand when exposed to heat without breaking, preventing liquid and gas molecules from traveling between cells. This makes closed-cell foam an excellent heat insulator.

Open-cell foam, in contrast, is lightweight, spongy, and soft. Its cell walls are broken, allowing air to fill the spaces. Due to its softness and weak structure, open-cell foam is ideal for cushions and padding. Additionally, it provides twice the sound resistance of closed-cell foam, making it an effective sound barrier.

Foam fabricators can enhance your product’s performance by creating custom foam products. They utilize custom molds, materials, colors, and various shapes and sizes. For more information on custom foam options, consult with a foam fabricator’s staff member.

Need help choosing the right foam material for your application? Consider the following factors:

- Density and Firmness: Higher-density foams provide more support and durability for applications like mattresses and orthopedic supports.

- Thermal and Acoustic Performance: Choose foam with the appropriate R-value or Noise Reduction Coefficient (NRC) for insulation and soundproofing projects.

- Chemical Resistance: Certain foams resist oils, solvents, and harsh chemicals, making them ideal for industrial gaskets and seals.

- Moisture Absorption: Closed-cell foams are best for wet environments, while open-cell foams are preferred where breathability is needed.

- Fire Retardance: Some foams meet UL or FMVSS fire safety standards for use in commercial and transportation applications.

If you have specific requirements, such as compliant materials for medical devices or food contact, be sure to discuss these with your foam fabricator to ensure regulatory compliance and optimal product performance.

Foam Fabrication Process

Fabricators create foam by mixing polymers with a gassing agent and other chemicals. The addition of the gassing agent causes the material to expand, forming a foam strip composed of countless gas bubbles. This foundational process sets the stage for various foam products used across numerous industries.

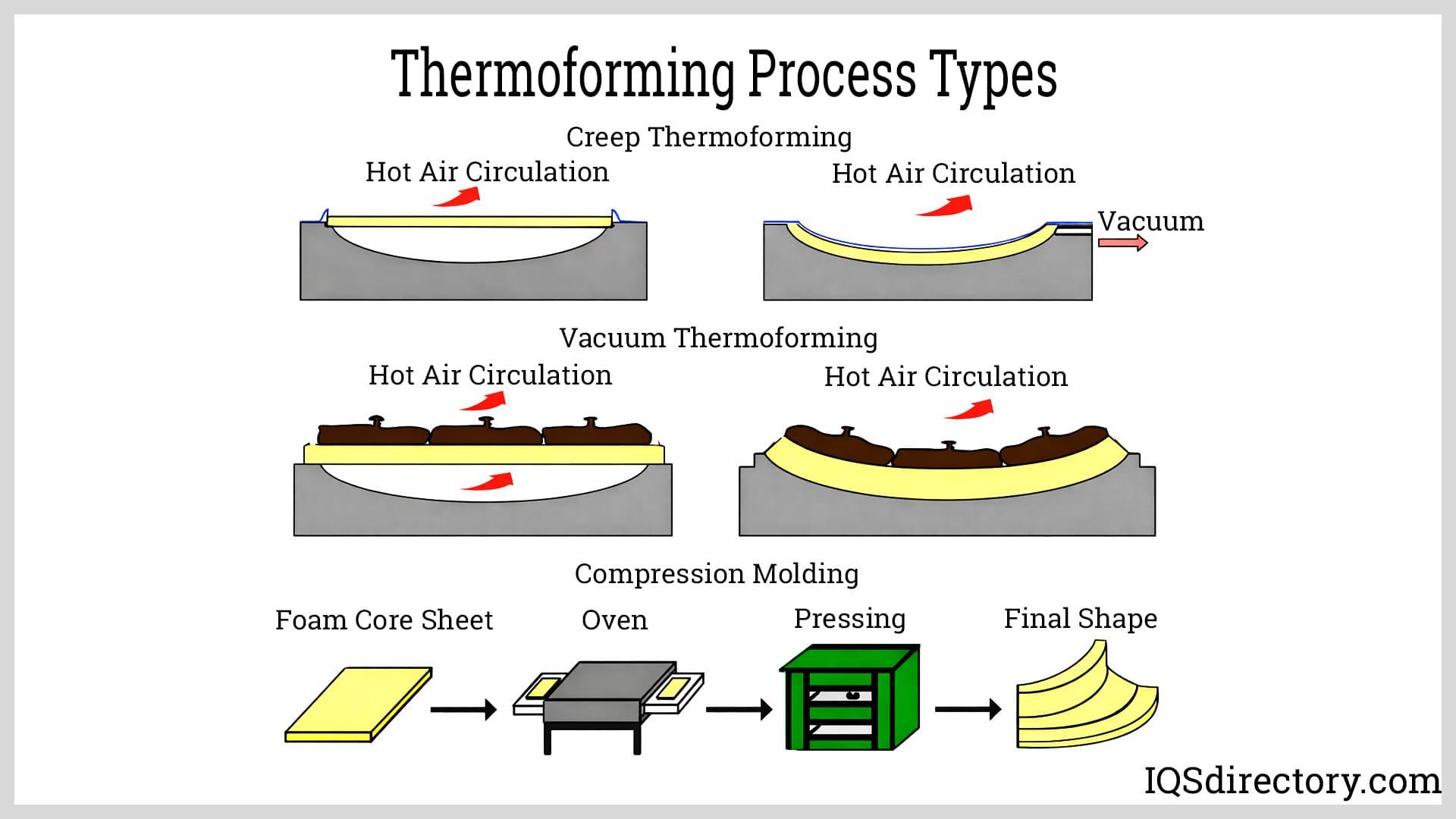

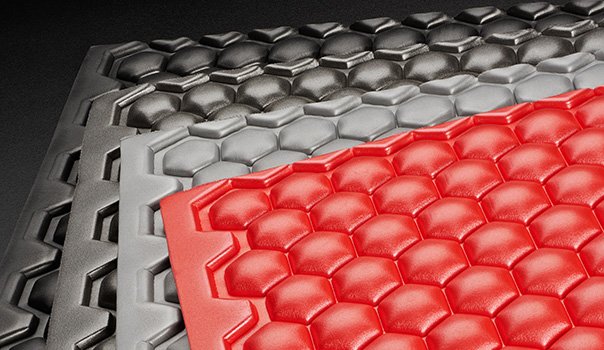

Once the foam is formed, it is shaped and refined through several fabrication processes. Die cutting involves cutting different shapes out of foam strips, sheets, or blocks. Waterjet cutting serves a similar purpose but uses a high-pressure water stream for more precise cuts. Thermoforming, the most popular method, involves heating bulk foam materials to form specific shapes. Foam felting compresses and cures thick, soft foam to produce denser materials. Each method tailors the foam to meet specific application needs.

Additional foam fabrication techniques include CNC routing for intricate shapes, lamination for multi-layered products, adhesive bonding, hot wire cutting for polystyrene foam, and custom molding for complex three-dimensional components. These processes enable the production of everything from simple foam inserts to highly engineered foam assemblies for aerospace and medical industries.

The foam fabrication process generates a significant amount of scrap, particularly during die cutting. Scrap can result from changes in the converting process, the shutdown and startup of production lines, or the leftover material after shapes are cut. Additionally, foam products produce scrap when they reach the end of their useful life. To manage this waste, fabricators primarily turn to recycling, driven by environmental concerns and stricter regulations on carbon dioxide emissions. Burning foam scrap, once a common practice, has declined due to its environmental impact and the preference for more sustainable disposal methods.

Looking to optimize your manufacturing process with custom foam fabrication? Ask about lean production methods, automated cutting, and waste reduction strategies to lower costs and improve product consistency.

Benefits Of Foam Fabrication

Foam fabricating offers several significant advantages. Firstly, it is highly versatile, allowing the creation of foams with a wide range of properties, from extreme stiffness to high pliability. Additionally, foam-fabricated parts are generally lighter than those produced through other methods, benefiting applications like automotive manufacturing that require lightweight components. Furthermore, foam fabricating produces excellent insulators, making it ideal for acoustic, vibration, and thermal insulation applications.

Economically, foam fabricating is particularly cost-effective for bulk production. Manufacturers can utilize scrap foam, which can be rebounded, shredded, and repurposed for products such as carpet padding or furniture filler. This recycling process helps companies maximize their return on investment by preventing the loss associated with burning scrap materials.

Additional benefits of foam fabrication include:

- Customizability: Foam can be precisely engineered for hardness, resilience, color, thickness, and size, meeting unique application requirements.

- Durability and Longevity: Many foam products are UV, moisture, and chemical resistant, ensuring performance in harsh environments.

- Cost-Effectiveness: Foam is lightweight, reducing shipping expenses and simplifying installation in large-scale projects.

- Energy Efficiency: Foam insulation improves building energy efficiency, reducing heating and cooling costs.

- Health and Safety: Medical-grade foams offer hypoallergenic, antimicrobial, and skin-safe options for healthcare and personal care products.

Looking to increase product value with advanced foam solutions? Explore multi-functional foam that combines insulation, sound absorption, and impact protection in a single component.

Things to Consider

If you are interested in fabricated foam, it is essential to work with an experienced fabricator to guide you through the process. Given the popularity of foam fabricating, many companies offer these services, but their quality can vary significantly. To assist you, we have compiled a list of high-quality, top-rated fabricated foam product converters, which you will find below.

Before reviewing these options, we recommend creating a detailed list of your own specifications. This list should include your requirements, product volume, budget, timeline, and preferred delivery method. With your list in hand, begin exploring the fabricator websites we’ve provided. Compare their offerings to your specifications, select three or four that meet your needs, and reach out to them. Discuss your project in detail to ensure they can deliver the best service. Once you have gathered enough information, choose the fabricator that best aligns with your requirements and proceed with your project.

Still have questions about the foam fabrication process or which material will best fulfill your technical and regulatory requirements? Use our internal search prompts:

- What are the key differences between polyurethane foam and polyethylene foam?

- How do I select a foam fabricator for medical or aerospace applications?

- What certifications should my foam products have for commercial construction?

- How do custom foam inserts improve packaging safety and efficiency?

- What is the best way to recycle or dispose of industrial foam scrap?

For detailed answers or to request a quote, consult our foam fabricator directory or reach out directly to a specialist.

Key Decision Factors When Choosing a Foam Fabricator

Selecting the right foam fabrication company is critical to project success. Consider these decision points:

- Industry Experience: Choose a provider with a proven track record in your sector (automotive, medical, electronics, construction, etc.).

- Material Capabilities: Ensure the fabricator offers the foam materials and grades you require, including specialty and fire-retardant foams.

- Quality Control: Look for ISO or other relevant certifications that guarantee consistent product quality and traceability.

- Lead Times: Ask about average turnaround times, especially for custom projects or large-volume orders.

- Engineering Support: Access to in-house design, prototyping, and testing can accelerate development and minimize errors.

- Sustainability Practices: If environmental responsibility matters to your operation, inquire about recycled content, waste reduction, and green manufacturing initiatives.

Evaluating these factors will help you narrow down the list of potential partners and ensure a successful sourcing experience for your foam-fabricated components.

Emerging Trends in Foam Fabrication

The foam fabrication industry continues to evolve with new technologies and market demands. Some current trends include:

- Advanced Computer-Aided Design (CAD): Integrating CAD and CAM systems allows for rapid prototyping and highly precise custom foam parts.

- Sustainable Materials: The rise of biodegradable, bio-based, and recycled foams reflects growing environmental awareness.

- Smart Foam Applications: Embedding sensors in foam for medical devices, automotive seats, and wearable technology.

- Fire-Resistant and Low-Emission Foams: Meeting stricter regulatory standards for indoor air quality and public safety.

- Multi-Functional Foams: Combining thermal, acoustic, and vibration control in a single product.

Are you planning to incorporate the latest innovations into your foam products? Consult with a foam fabrication expert to discuss custom solutions that leverage cutting-edge materials and processes.

Common Questions About Foam Fabrication

- What is the difference between die cutting and waterjet cutting for foam?

- Can foam be fabricated to meet FDA, UL, or automotive standards?

- How does the choice of foam density impact comfort and durability?

- What are the best practices for storing and handling foam products?

- How do I request a sample or prototype before bulk production?

For more answers and to connect with leading foam fabricators, visit our comprehensive company listings.

Start Your Foam Fabrication Project

Whether you need protective packaging, precision gaskets, medical-grade cushions, or high-performance insulation, foam fabrication offers a tailored solution. From selecting the right foam material to optimizing your product design and ensuring regulatory compliance, experienced foam fabricators deliver the expertise and technology to bring your vision to life.

Ready to get started? Review our listings, request a quote, and partner with a trusted foam fabricator to achieve superior results in your next project.

Check out our Polyurethane Molding website

Check out our Gaskets website

What are the main applications of fabricated foam?

Fabricated foam is used in a wide range of industries for insulation, sealing, liquid absorption, vibration dampening, cushioning, protection, soundproofing, filtration, and structural support. Specific applications include automotive cushioning and NVH insulation, construction insulation and soundproofing, medical pads and supports, custom packaging, and acoustic panels for studios.

What is the difference between open-cell and closed-cell foam?

Open-cell foam is lightweight, flexible, and allows air flow, making it suitable for cushions, soundproofing, and filtration. Closed-cell foam is denser, moisture-resistant, and provides superior durability and insulation, making it ideal for structural support, flotation, and thermal insulation.

How is foam fabricated and shaped for custom products?

Foam is created by mixing polymers with a gassing agent to form material with tiny bubbles. Shaping is done through processes such as die cutting, waterjet cutting, thermoforming, CNC routing, lamination, adhesive bonding, and molding. These methods allow foam to be custom-formed for specific applications and industries.

How do I choose the right foam material for my application?

Consider factors such as density and firmness, thermal and acoustic performance, chemical resistance, moisture absorption, and fire retardance. The intended use, required certifications, and environmental conditions will help determine whether polyurethane, polyethylene, cross-linked polyethylene, or another foam type best suits your needs.

What are the benefits of using fabricated foam products?

Fabricated foam offers customizability, durability, cost-effectiveness, energy efficiency, and health and safety benefits. Foam is lightweight, can be engineered for specific characteristics, is often recyclable, and is widely used for insulation, packaging, medical products, and impact absorption.

How can foam scrap and waste be managed sustainably?

Foam scrap from production and end-of-life products can be recycled, rebonded, or shredded for use in products like carpet padding and furniture filler. Sustainable practices also include using eco-friendly materials, reducing production waste, and avoiding the burning of foam scrap to minimize environmental impact.

What factors should I consider when selecting a foam fabricator?

Key factors include industry experience, material capabilities, quality control certifications, lead times, engineering support, and sustainability practices. A fabricator’s expertise, resources, and compliance with relevant standards ensure your project’s success and product quality.

Die Cutting

Die Cutting Foam Fab

Foam Fab Gaskets

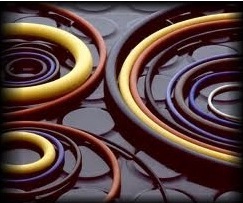

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services