Rubberlite, Inc.

Rubberlite, Inc.Request A Quote

Huntington, WVRubberlite is a leading foam fabricator that specializes in the design and manufacture of high-quality, closed-cell foam products. The company has over 60 years of experience in the foam fabrication industry, with a strong focus on innovation, quality, and customer service. Rubberlite's foam products are used in a variety of applications, including medical equipment, footwear, sporting goods, packaging, and industrial products. The company offers a wide range of foam materials, including EVA, polyurethane, neoprene, and PVC, among others. These materials can be customized to meet specific customer requirements, such as density, thickness, and color. One of Rubberlite's core competencies is its foam fabrication capabilities. The company uses advanced manufacturing technologies to produce foam products in a wide range of shapes and sizes. Rubberlite's foam fabrication services include die cutting, laminating, slitting, and CNC routing, among others. These processes enable the company to create custom foam products that meet specific customer needs and industry standards. Rubberlite's team of experienced engineers and designers works closely with customers to understand their unique requirements and develop innovative solutions. The company's expertise in foam design and engineering allows it to provide customers with value-added services such as product development, prototyping, and testing. Rubberlite's commitment to quality is evident in its ISO 9001:2015 certification, which ensures that the company's products and services meet or exceed the highest industry standards. The company also follows strict quality control procedures to ensure that its foam products are of the highest quality and consistency. In addition to its foam fabrication capabilities, Rubberlite offers a range of value-added services to its customers. These include inventory management, custom packaging, and logistical support. The company's focus on customer service and support is a key factor in its success, and it is committed to providing its customers with the highest level of service and support. Rubberlite's dedication to innovation, quality, and customer service has made it a trusted partner for businesses across a wide range of industries. The company's foam products are known for their durability, reliability, and high-performance characteristics. With its extensive experience, advanced manufacturing capabilities, and commitment to customer satisfaction, Rubberlite is well-positioned to continue its leadership in the foam fabrication industry.

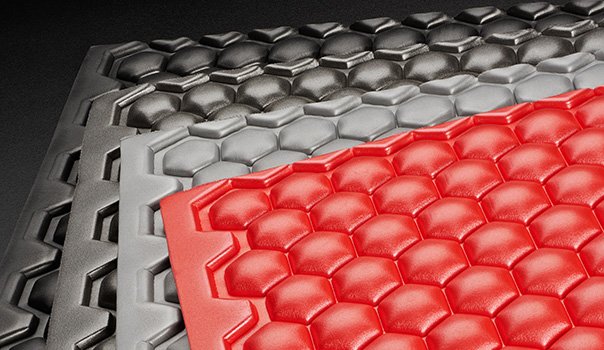

Die Cutting

Die Cutting Foam Fab

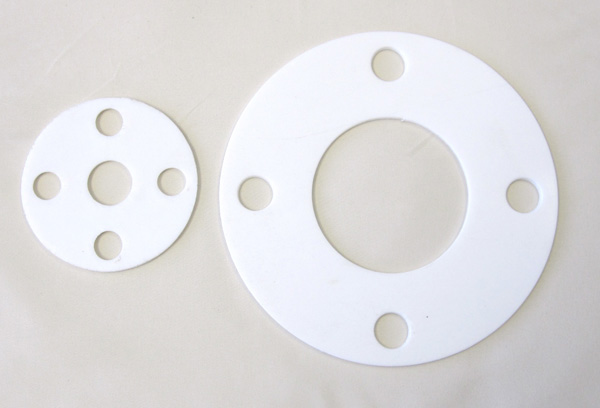

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

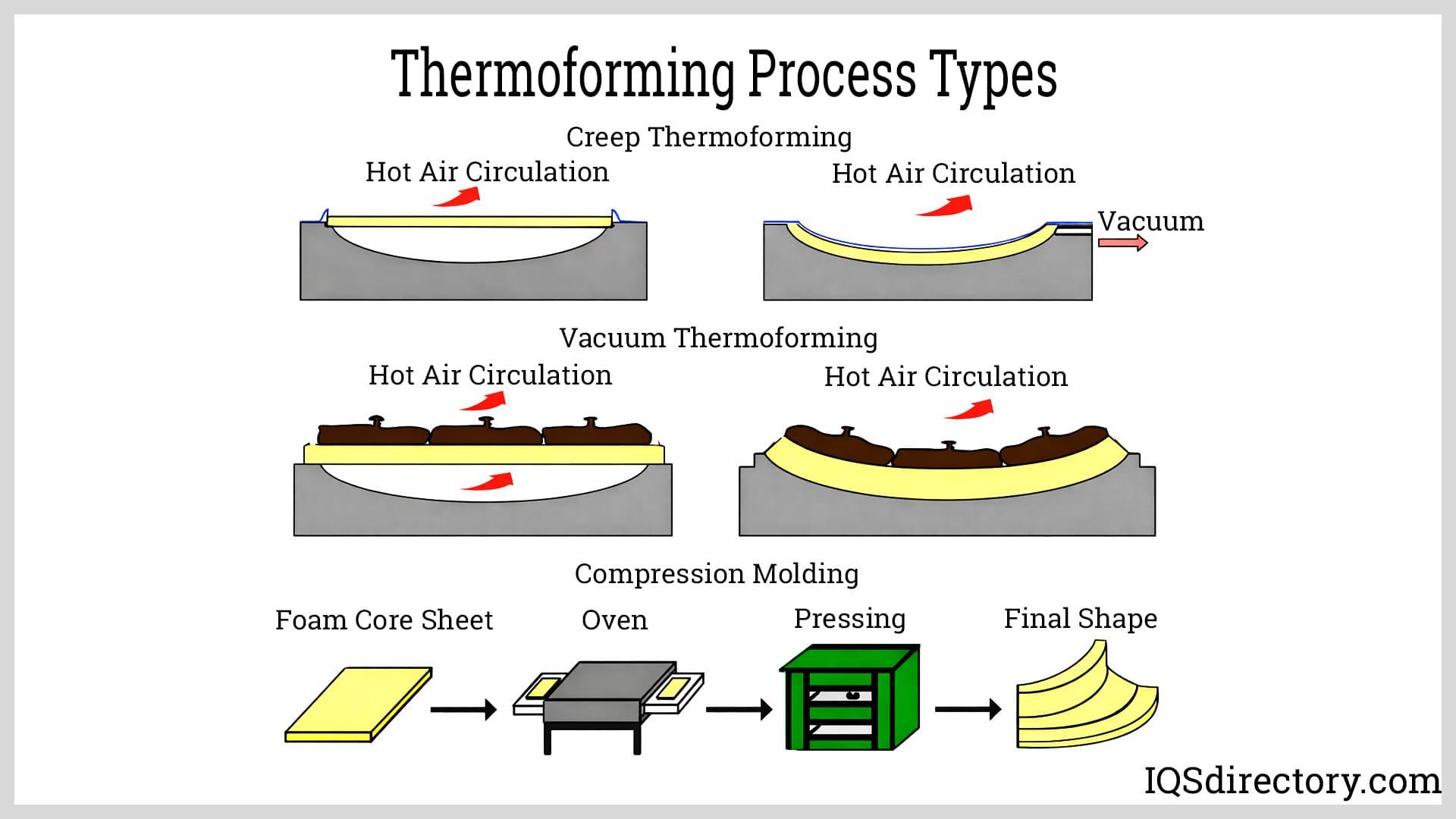

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services