Rogers Foam Corporation

Rogers Foam CorporationRequest A Quote

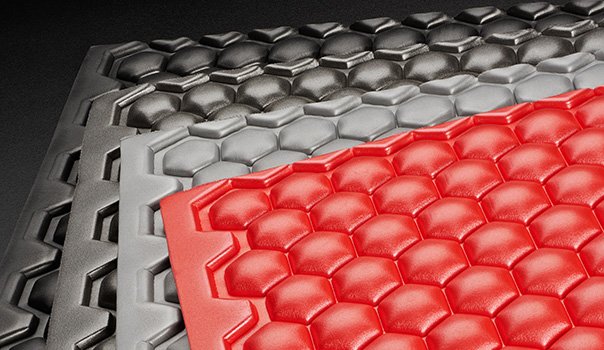

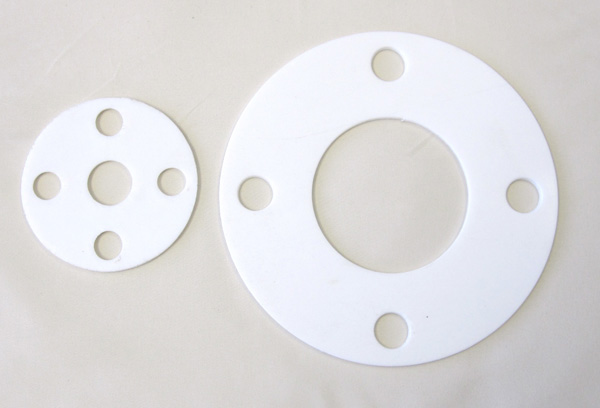

Somerville, MARogers Foam Corporation is a leading provider of foam fabrication products and services. Founded in 1947 and headquartered in Somerville, Massachusetts, the company has over 70 years of experience in providing high-quality foam solutions to its customers. Rogers Foam Corporation specializes in foam fabrication, which involves the conversion of foam materials into various shapes and forms. The company uses a variety of foam materials, including polyurethane foam, polyethylene foam, and cross-linked polyethylene foam, to create a wide range of products for its customers. These products can be used in various industries, such as automotive, aerospace, construction, and medical. Rogers Foam Corporation has a team of experienced engineers and designers who work closely with customers to understand their specific needs and requirements. Using state-of-the-art equipment and advanced technology, the company can design and fabricate custom foam products that meet the highest standards of quality and performance. Some of the foam products offered by Rogers Foam Corporation include foam gaskets, foam seals, foam padding, foam insulation, and foam packaging. The company also provides foam cutting, laminating, and adhesive bonding services to create finished products that are ready for use. Rogers Foam Corporation has a strong commitment to customer satisfaction and quality control. The company is ISO 9001:2015 certified, which means that it follows a strict quality management system to ensure that its products and services meet or exceed customer expectations. In addition to foam fabrication, Rogers Foam Corporation also provides foam recycling services to help customers reduce waste and minimize their environmental impact. The company can recycle foam materials and turn them into new products, reducing the amount of waste that ends up in landfills. Overall, Rogers Foam Corporation is a reliable and innovative provider of foam fabrication products and services. With its extensive experience, advanced technology, and commitment to quality, the company is well-positioned to meet the diverse needs of its customers across various industries.

Leading Foam Fabricating Companies

More Foam Fabricating Companies

Additional Categories: Floor Gratings, Flow Meters

Die Cutting

Die Cutting Foam Fab

Foam Fab Gaskets

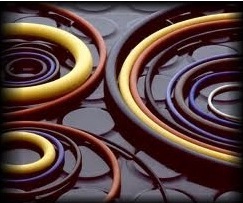

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services