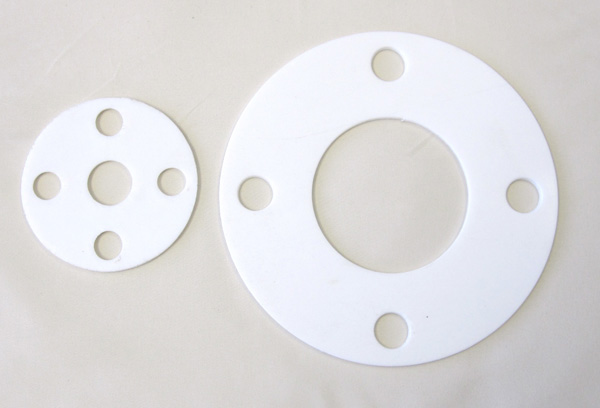

Fabricators can create all different kinds of medical foam in order to suit your needs. Applications include: custom orthotics, long-term wound dressing (fluid management and cushioning), prosthetic padding, pressure relief, medical device cushioning, medical device sealing and gasketing, artificial stoma equipment sealing, keypad/control panel sealing, medical device LCD screen sealing and electrode attachment. Read More…

The applications for foam fabricating are only limited by one’s imagination; that is our slogan at American Excelsior. We are a foam supplier who offers many different foam cushions & foam padding for over a dozen industries.

Since 1992, Flextech has delivered innovative, custom engineered foam solutions. We combine our engineering and design services with our unique foam lamination, fabrication, and thermoforming capabilities, to provide quality foam components to a diverse customer base. Our customers include OEM’s in the medical, industrial, military, aerospace and consumer products markets. We invite you to...

Deluxe Packaging works hard to always create cost-effective solutions and services for our clients better than anyone else. We offer a full array of high quality products, including polyurethane foam, polystyrene foam, and polyethylene foam. Our products are customizable to match a product’s fragility and size. Deluxe Packaging is your complete packaging solution provider for all of your...

Here at Thrust Industries we provide die cut foam that comes in a variety of shapes and configurations. We die cut foam from a number of materials including: urethane, PVC, polyester, neoprene, ether, cellular, volara, and much more.

More Medical Foam Companies

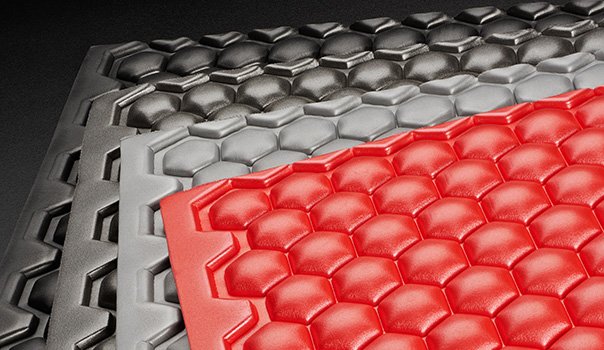

Depending on your needs, medical foam may need to meet a wide array of requirement categories. When designing your medical foam, fabricators decide in the official way(s) in which your medical foam will qualify as such. Ways to register foam as medical grade foam include: getting it to pass and be certified by ISO 10993 standards (biocompatibility), using raw material registered by the FDA (fixed formulation), using a foam formulation registered with the FDA master file (must also pass biocompatibility tests to qualify), and/or using raw materials registered with a USP classification for the pharmaceutical industry. Fabricators can also potentially work with raw materials that have reached pre-market approval. Fabricators can customize your foam in a number of ways, including by shape, density, color and thickness. They can also laminate them with adhesives like silicone to make them better suited for your application. Fabricators may sell you open cell foam for absorbency, or closed cell foam for water resistance.

They can make your foam soft, moldable and flexible or hard and compression resistant. For application to the body, medical foam fabricators will make their product lightweight and breathable. It all depends on your needs.

To discuss said needs with an experienced medical foam supplier, talk to one or more of the companies we have listed on this page. All of those with whom we work have proven their worth and trustworthiness time and time again. Start browsing to get started. Good luck!

Die Cutting

Die Cutting Foam Fab

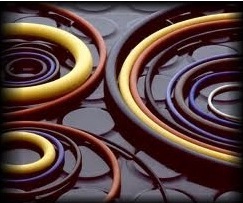

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services