Foam Inc.

Foam Inc.Request A Quote

Aurora, IL | 844-362-6462At Foam Inc., we define ourselves as dedicated foam fabricators focused on delivering materials and components that offer precision, consistency, and reliable performance across a wide range of applications. We work with an extensive selection of foam types and densities, giving us the flexibility to create solutions that support cushioning, insulation, protection, filtration, and structural needs. Through careful material sourcing and controlled fabrication processes, we produce foam products that meet strict dimensional, mechanical, and functional requirements. We approach every project with a collaborative mindset, helping customers refine their designs and select the ideal foam for their application. Our capabilities include cutting, shaping, laminating, bonding, and custom assembly, allowing us to produce everything from simple pads to highly engineered components. By understanding how foam behaves under compression, impact, and environmental exposure, we guide our customers toward solutions that balance performance with cost and long-term durability. Our internal quality standards ensure that every part integrates smoothly into downstream assembly or end-use environments.

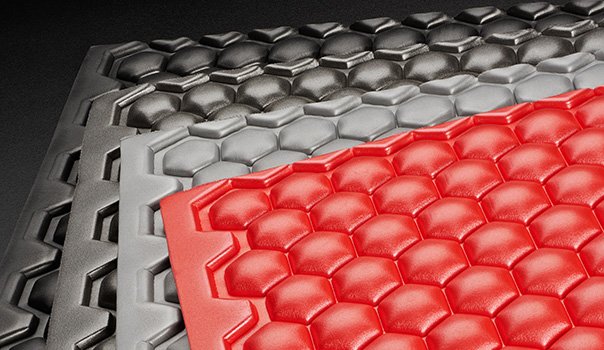

Die Cutting

Die Cutting Foam Fab

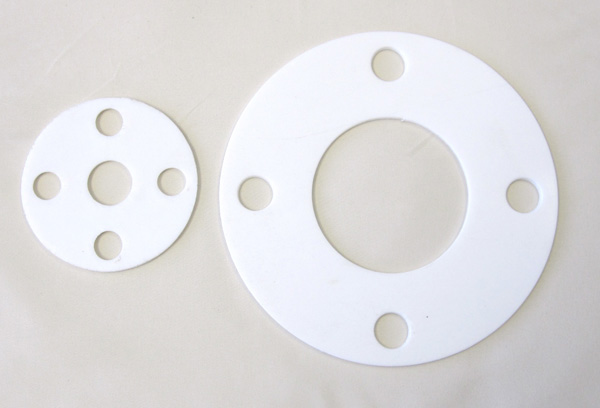

Foam Fab Gaskets

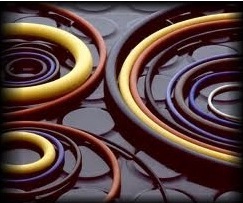

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

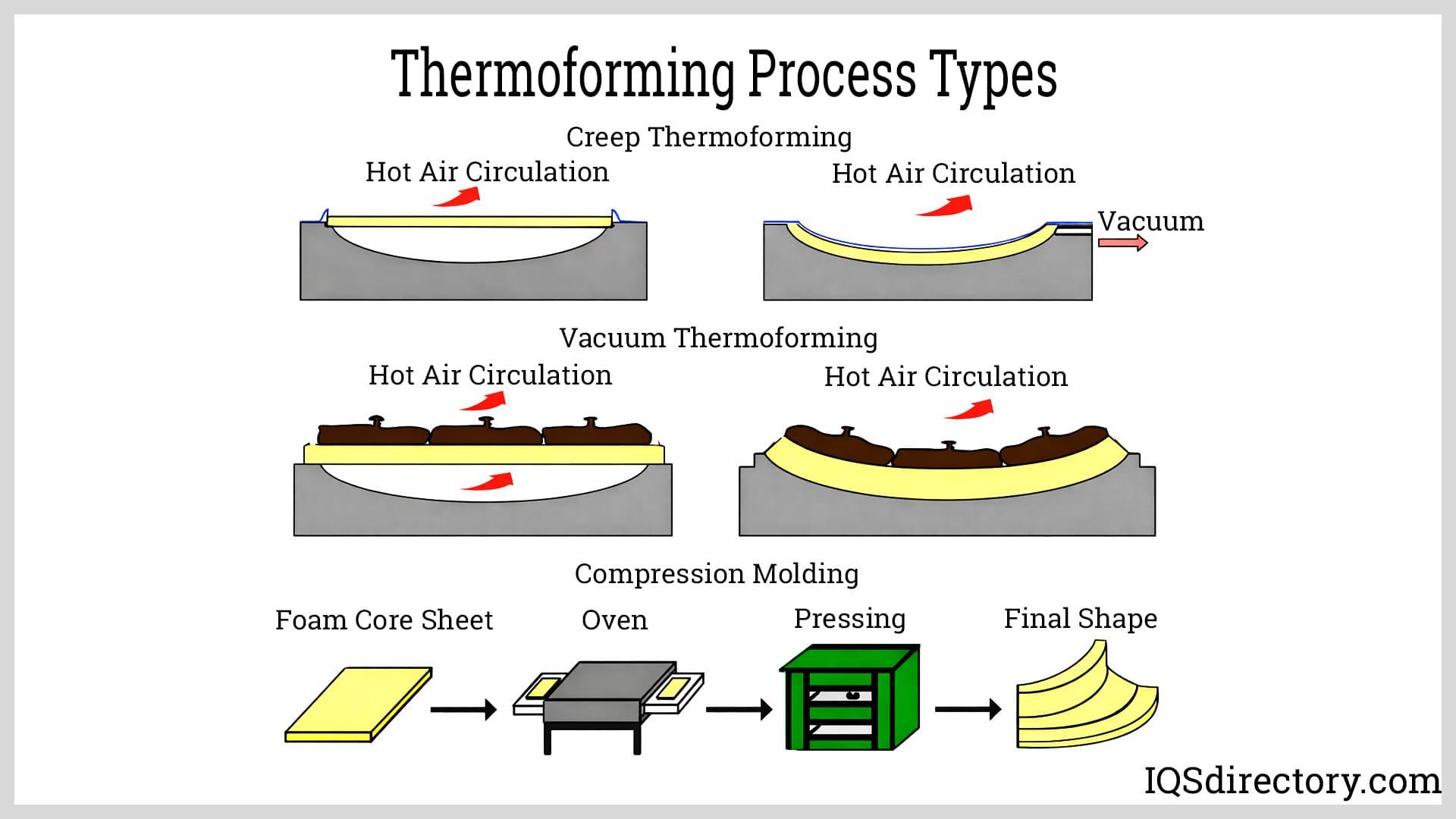

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services