The fabrication of foam begins with various types of polymers such as polyether, polyester, Volara, or ethafoam, which can be shaped, configured, and formed into any type of complex design. In recent years, there has been a surge in the use of foam products due their durability and longevity as well as serving as excellent protection. Read More…

The applications for foam fabricating are only limited by one’s imagination; that is our slogan at American Excelsior. We are a foam supplier who offers many different foam cushions & foam padding for over a dozen industries.

Since 1992, Flextech has delivered innovative, custom engineered foam solutions. We combine our engineering and design services with our unique foam lamination, fabrication, and thermoforming capabilities, to provide quality foam components to a diverse customer base. Our customers include OEM’s in the medical, industrial, military, aerospace and consumer products markets. We invite you to...

Deluxe Packaging works hard to always create cost-effective solutions and services for our clients better than anyone else. We offer a full array of high quality products, including polyurethane foam, polystyrene foam, and polyethylene foam. Our products are customizable to match a product’s fragility and size. Deluxe Packaging is your complete packaging solution provider for all of your...

Here at Thrust Industries we provide die cut foam that comes in a variety of shapes and configurations. We die cut foam from a number of materials including: urethane, PVC, polyester, neoprene, ether, cellular, volara, and much more.

More Foam Fabricator Companies

What is Foam for Fabrication?

When the word foam is used, it must be understood that it relates to a wide assortment of materials, including rubber, that are used to create foam materials. Polymeric foam is formed from various types of polymers. Rubber foam is formed from the methods used to produce synthetic rubber. The type of foam depends on the application for which it is being produced as foam for insulation is radically different from foam used for packing and shipping.

The qualities of each type of foam define how it is used and its purpose. Foam fabricators carefully select the correct type of foam material for the production of foam products such that they exactly fit the application. Fabricators do not specialize in any one type of foam but offer a variety of types to meet customer requirements.

Definition of Foam Types

When defining foam types, the first consideration is the type of cells. The initial definition of foam types specified by foam fabricators is open and closed cell. When it is necessary for a foam product to be soft, flexible, and pliable, the type of foam being used is the open type where there are large open spaces in the foam that permit air to be trapped. A common form of this type of foam is in pillows.

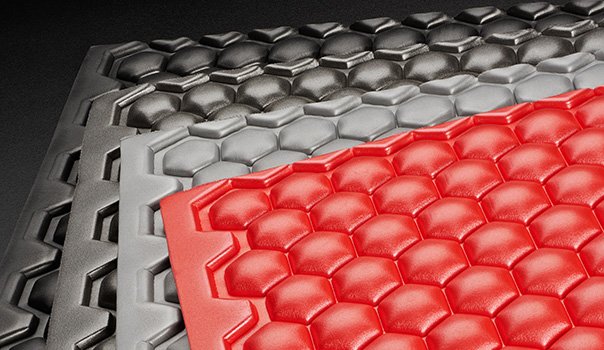

A denser version of foam is the closed cell type, which is stiff and solid. It can be used to support walls, be material for bumpers on cars, or be sprayed in as insulation. Since closed foam is rigid and stiff, it is produced in sheets to be cut, compressed, or molded into several shapes for applications that require sturdy solid material.

Different Types of Foam Fabricator Materials

Foam fabricators are constantly developing new uses for foam materials. In certain cases, specialty foams that are specifically designed for unusual applications are formulated to meet industry requirements. This has led to the development of off shoots of foam that are related to the normal varieties but have properties to fit unique conditions.

A common type of open cell foam is polyether, which is light, compressible, flexible, and tear resistant. A vital part of the characteristics of polyether foam is its resistance to the growth of mold, fungus, and mildew, which makes it suitable for climates with high humidity. This type of foam is used for medical devices and sports gear.

Polyester foam is made from the same root polymer as polyether foam, which is the polyurethane family of polymers. Of the two types of polymers, polyester was developed first and has high tensile strength and hardness. These characteristics make it the main choice for the textile industry. A special feature of polyester foam for foam fabricators is its resistance to hydrocarbons and alcohol.

Volara foam is a cross linked low density polyethylene (LDPE) that has excellent chemical resistance. This type of foam is used by foam fabricators for applications that require thermal insulation, low water absorption, and resistance to abrasion. Its main use is as a protective material for boxes and display cases.

When protection is needed for electronics, foam fabricators normally choose ethafoam since it is a denser foam with exceptional shock absorption characteristics. It is a closed cell foam that is adaptable to a wide variety of applications and has the durability to withstand impact and pressure. Since it is flexible and customizable, it is used for the storage of valuables.

The few foam materials described above are a sampling of the many types of foam materials available to foam fabricators. When a process demands a foam material, fabricators carefully select the right product for the application.

Die Cutting

Die Cutting Foam Fab

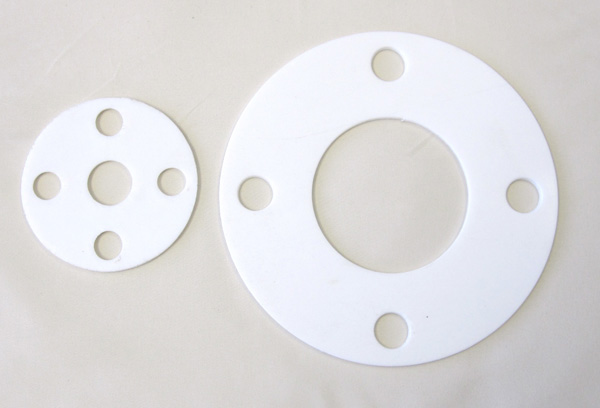

Foam Fab Gaskets

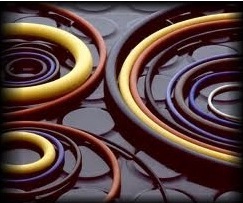

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services