Foam cutting is the most common method of foam fabrication. In stock form, foam is most commonly stored and transported in buns, sheets and rolls which then require secondary processing in order to meet the desired shapes and sizes of its intended use. Read More…

The applications for foam fabricating are only limited by one’s imagination; that is our slogan at American Excelsior. We are a foam supplier who offers many different foam cushions & foam padding for over a dozen industries.

Since 1992, Flextech has delivered innovative, custom engineered foam solutions. We combine our engineering and design services with our unique foam lamination, fabrication, and thermoforming capabilities, to provide quality foam components to a diverse customer base. Our customers include OEM’s in the medical, industrial, military, aerospace and consumer products markets. We invite you to...

Deluxe Packaging works hard to always create cost-effective solutions and services for our clients better than anyone else. We offer a full array of high quality products, including polyurethane foam, polystyrene foam, and polyethylene foam. Our products are customizable to match a product’s fragility and size. Deluxe Packaging is your complete packaging solution provider for all of your...

Here at Thrust Industries we provide die cut foam that comes in a variety of shapes and configurations. We die cut foam from a number of materials including: urethane, PVC, polyester, neoprene, ether, cellular, volara, and much more.

More Foam Cutting Companies

What is Foam Cutting?

Foam cutting is the process of cutting foam to meet the required shape and size for the application by contour cutting, die cutting, hot wire cutting, laser or water jet cutting.

Foam is a variable, polymer-based material which is used in a broad range of applications in industries as carried as construction, aerospace, medical and marine.

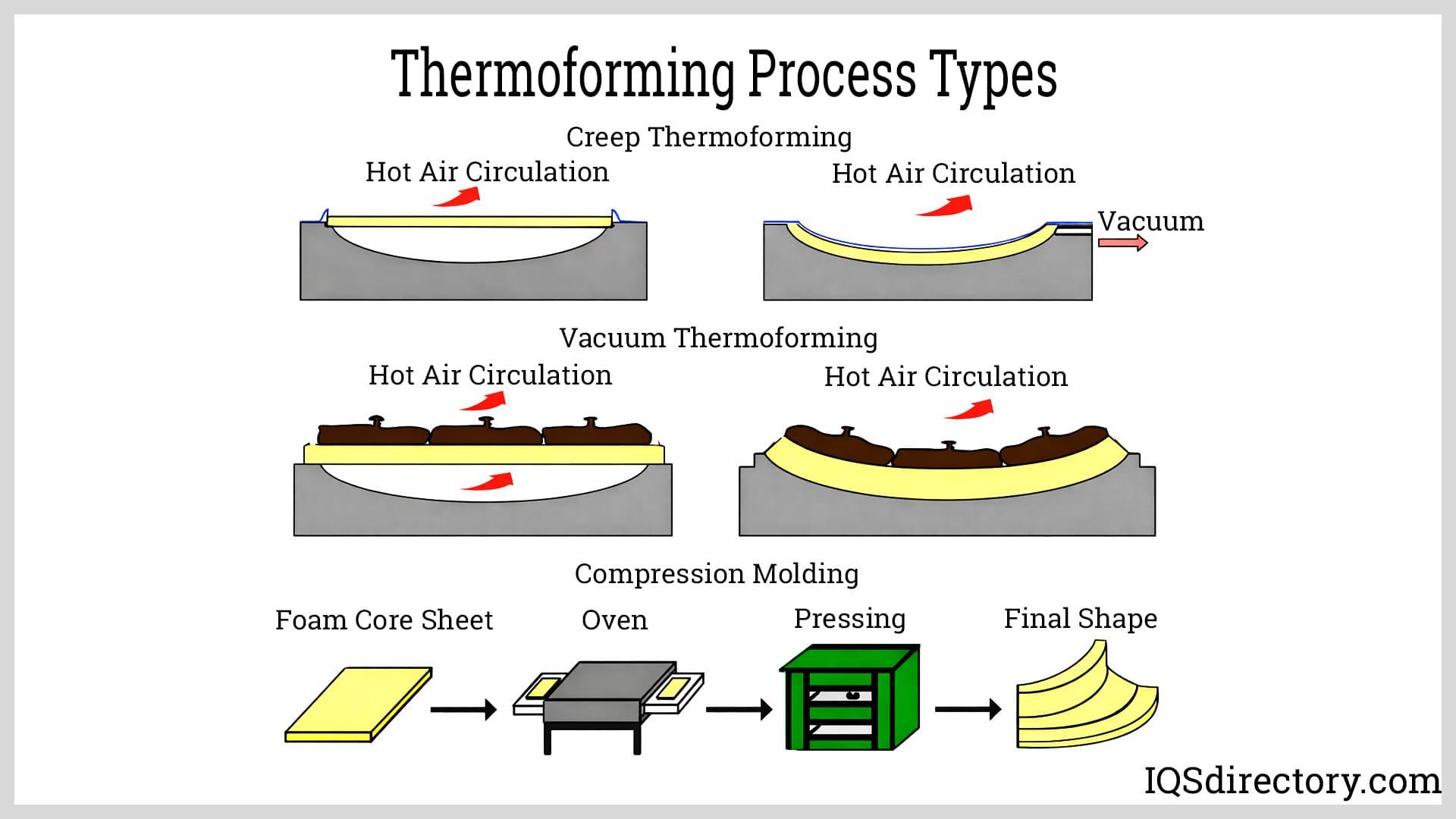

While a thermoset and molding process can also be used to fabricate some specifically shaped foam parts, most products are constructed from cutting foam in desired shapes, or into parts of shapes that are then joined by adhesive into the final product. Foam is used for a number of insulation and structuring purposes, as well as in signage, architectural modeling and props, aerospace applications, medical applications, foam cushioning for sports and recreational equipment, air and liquid filtration, packaging and energy absorption.

It is a material that is able to be used in an almost limitless range of applications due to the ways in which it can differ and be adapted in terms of shape, size, softness and density. Specific applications require different types of foam such as polyurethane or polyethylene, and in the same way, different types of foam cutting. All these factors should be carefully considered when determining the best type of foam and method of fabrication.

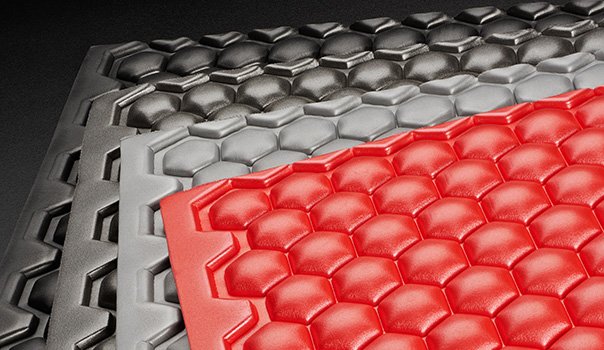

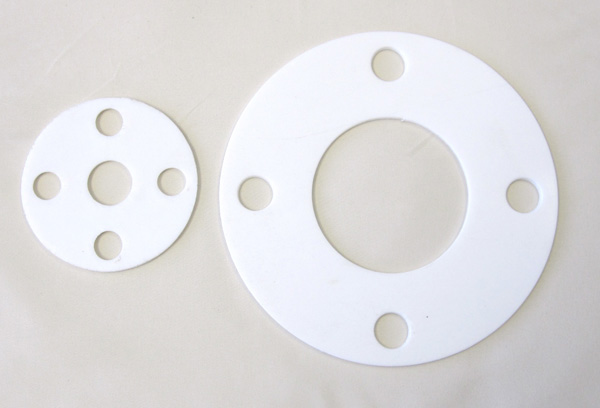

The process of foam cutting can be achieved by contour cutting, die cutting, hot wire cutting, laser or water jet cutting. Contour cutting uses a specialized saw that cuts into a foam block in the desired pattern or shape. Foam die cutting uses a process similar to stamping to produce parts from a solid piece of foam.

For long duration runs, this is a consistent and efficient method of parts cutting. Another common and precise foam cutting method is hot wire cutting. This process uses a taut metal wire instead of a saw blade. The wire is heated through electrical resistance until it is hot enough to melt, or vaporize, the foam. It passes through the material at the desired location and vaporizes the foam before it comes into contact with it.

The speed of the process has to be carefully considered so as not to drag the wire and damage the foam if too fast, or create an unnecessarily wide cut if pulled through too slow. The depth of the cut is limited only by the length of the cutting wire and this is restricted by wire's tendency to sag under the force of gravity.

Die Cutting

Die Cutting Foam Fab

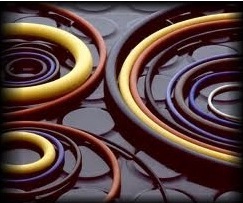

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services