Foam is a synthetically fabricated material that can be used in a variety of industrial and commercial applications as cushioning, structural support and insulation. There are two general classifications of foam: open cell structured foam and closed cell structured foam. Read More…

The applications for foam fabricating are only limited by one’s imagination; that is our slogan at American Excelsior. We are a foam supplier who offers many different foam cushions & foam padding for over a dozen industries.

Since 1992, Flextech has delivered innovative, custom engineered foam solutions. We combine our engineering and design services with our unique foam lamination, fabrication, and thermoforming capabilities, to provide quality foam components to a diverse customer base. Our customers include OEM’s in the medical, industrial, military, aerospace and consumer products markets. We invite you to...

Deluxe Packaging works hard to always create cost-effective solutions and services for our clients better than anyone else. We offer a full array of high quality products, including polyurethane foam, polystyrene foam, and polyethylene foam. Our products are customizable to match a product’s fragility and size. Deluxe Packaging is your complete packaging solution provider for all of your...

Here at Thrust Industries we provide die cut foam that comes in a variety of shapes and configurations. We die cut foam from a number of materials including: urethane, PVC, polyester, neoprene, ether, cellular, volara, and much more.

More Foam Companies

In open cell foam, the pores, or cells, are interconnected and joined. The resulting foam is flexible and soft, able to be compressed and easily broken apart.

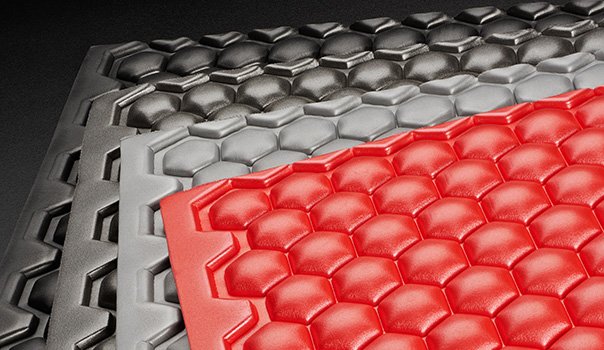

In closed cell foam, the cells are sealed from one another and are arranged in a compact configuration that results in firmer and pressure resistant foam as the cells do not join together or compress. Various synthetic polymers are used to fabricate foam materials, namely polyurethane, polyethylene, polyester and more. Each polymer provides characteristics that are desirable in certain applications.

Polyurethane foam is closed-cell foam that over time decomposes when exposed to sunlight. In this way, it is an environmentally friendly material choice, especially for products which do not require an exceptionally long life span. Polyethylene foam, on the other hand, is especially useful for shock and vibration absorption due to its cell configuration.

The foam itself is made by mixing the chemical elements and adding a gassing agent. The addition of a gassing agent causes the material to expand and form a strip of foam material. The length of time the process lasts for, combined with the intensity of the gassing agent will affect the porosity of the final product. The gas bubbles are essentially trapped in the polymer material allowing it to have an element of flexibility that a solid polymer would not have.

Stock rolls or buns of foam are the most common form in which it is stored and transported to fabricators, and then a number of foam fabricating services, such as foam cutting, can be performed in order for the foam to match the desired shape, size and dimensions of the final product. Water jet cutting, die cutting, hot wire cutting and more are all common techniques employed in the process of foam fabrication.

Common foam applications such as packaging, insulation, cushioning, acoustics and more use different foams. Characteristics that are true of almost every type of foam include lightweightness, compressibility, low thermal conductivity, low water vapor transmission, resiliency and resistance to mold, mildew and bacterial growth.

Less common than solid foam, liquid foam serves a number of specific applications and can be used as a fire retardant materials to fill gaps in construction projects, or in other settings to prevent the spread of fires, and to prevent air and water leakage. The reacting foam expands to fill the exact shape of the area in a way that solid foam or other materials could not.

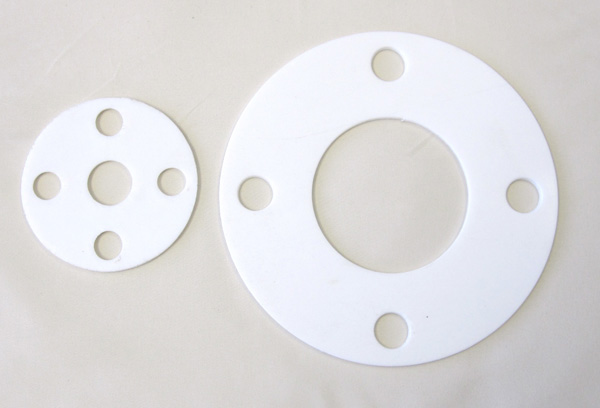

Die Cutting

Die Cutting Foam Fab

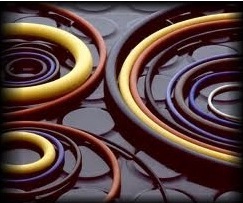

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services