The open cell structure and porosity of reticulated foam allow liquids and gases to pass through while still catching larger particles and contaminants, making it ideal for use as a filter material. Read More…

The applications for foam fabricating are only limited by one’s imagination; that is our slogan at American Excelsior. We are a foam supplier who offers many different foam cushions & foam padding for over a dozen industries.

Since 1992, Flextech has delivered innovative, custom engineered foam solutions. We combine our engineering and design services with our unique foam lamination, fabrication, and thermoforming capabilities, to provide quality foam components to a diverse customer base. Our customers include OEM’s in the medical, industrial, military, aerospace and consumer products markets. We invite you to...

Deluxe Packaging works hard to always create cost-effective solutions and services for our clients better than anyone else. We offer a full array of high quality products, including polyurethane foam, polystyrene foam, and polyethylene foam. Our products are customizable to match a product’s fragility and size. Deluxe Packaging is your complete packaging solution provider for all of your...

Here at Thrust Industries we provide die cut foam that comes in a variety of shapes and configurations. We die cut foam from a number of materials including: urethane, PVC, polyester, neoprene, ether, cellular, volara, and much more.

More Filter Foam Companies

While many other types of filters operate by catching particles on their surface, filter foams are depth-loading filters. This means that contaminants are captured within the body of the foam instead of just the outer surface.

Depth-loading is an ideal feature for filters used in applications for fluids with a higher concentration of particles. As it catches the higher volume of contaminants, the filter foam has more room within its structure to hold the contaminants without becoming clogged.

This structure and filtering process also helps improve the quality of the filter. Particles larger than the pore size of the filter get caught on the exterior of the foam, and they start to build up, forming what is called the cake layer. The cake layer serves as a secondary filter, catching even smaller particles.

Only the smallest particles are able to breach this outer layer, but once they enter into the foam structure, they are captured within the pockets, or cells, of the foam. Thus, filter foams are an incredibly useful filtration option.

Fabricators create many different kinds of filter foam. Filters can be converted from polyurethane, polyester, polyether, ceramic, and even metal. Polyether foams are often used in liquid filtration applications, polyester foams are used in gas filtration, and polyurethane foams can be used in many filtration applications, including vehicle air filters.

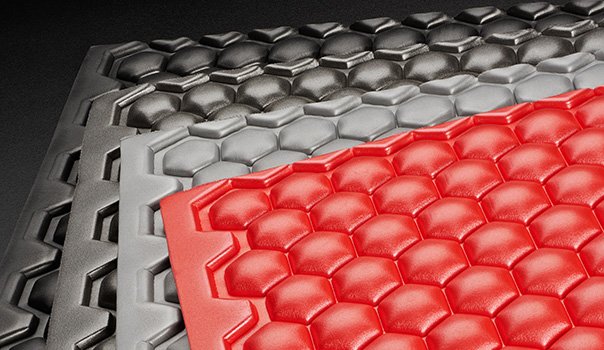

In addition to the material composition of the foam, other foam properties can also be manipulated to enhance and specialize filters. The size, shape, and distribution of the cells within the foam can be tailored to meet the porosity needs of different applications.

Filter Foam - Williams Foam

Filter Foam - Williams Foam

Die Cutting

Die Cutting Foam Fab

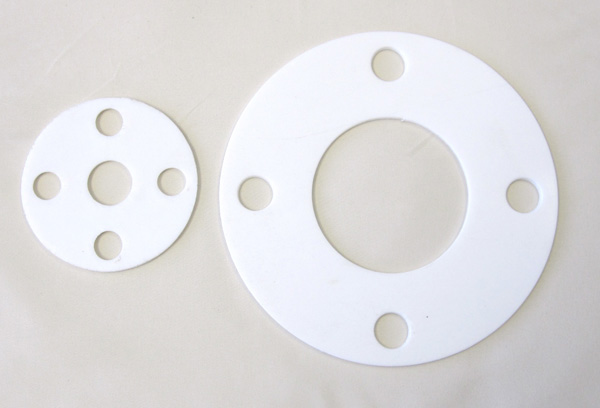

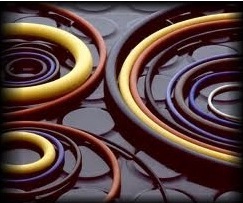

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services