Like regular polyethylene foam, crosslink foam is durable, rigid and resistant to substances like: bacteria, mold, mildew and rot. However, it is more compact, buoyant and water resistance than its non-crosslinked cousins. Read More…

The applications for foam fabricating are only limited by one’s imagination; that is our slogan at American Excelsior. We are a foam supplier who offers many different foam cushions & foam padding for over a dozen industries.

Since 1992, Flextech has delivered innovative, custom engineered foam solutions. We combine our engineering and design services with our unique foam lamination, fabrication, and thermoforming capabilities, to provide quality foam components to a diverse customer base. Our customers include OEM’s in the medical, industrial, military, aerospace and consumer products markets. We invite you to...

Deluxe Packaging works hard to always create cost-effective solutions and services for our clients better than anyone else. We offer a full array of high quality products, including polyurethane foam, polystyrene foam, and polyethylene foam. Our products are customizable to match a product’s fragility and size. Deluxe Packaging is your complete packaging solution provider for all of your...

Here at Thrust Industries we provide die cut foam that comes in a variety of shapes and configurations. We die cut foam from a number of materials including: urethane, PVC, polyester, neoprene, ether, cellular, volara, and much more.

More Crosslink Foam Companies

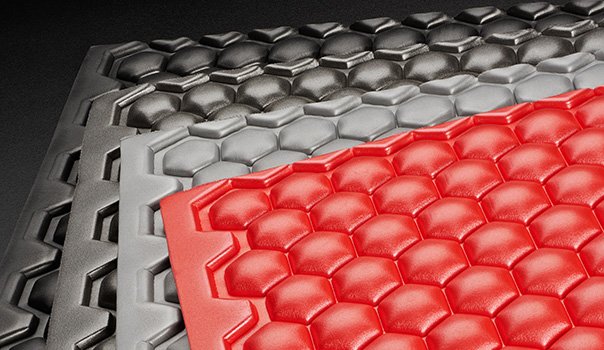

It also has better chemical properties. For this reason, crosslink foam can protect more surfaces than regular foam, including Class A automotive parts. While generally thicker than regular polyethylene foam, crosslink foam is also much finer and more aesthetically pleasing; it comes with a high quality finish.

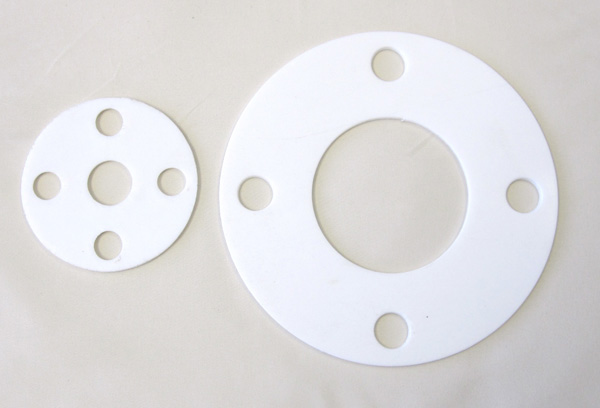

Crosslinked foam works very well as packaging material, cushioning material and thermal insulation. Most often, people use it to package and protect medical devices, cables, military tools and automotive parts. It is also used to fabricate: protective case inserts, soft orthopedic products, foam tape, helmet lining, industrial gaskets, construction expansion joints, tubing, toys, flotation devices, camp sleeping mats and exercise mats.

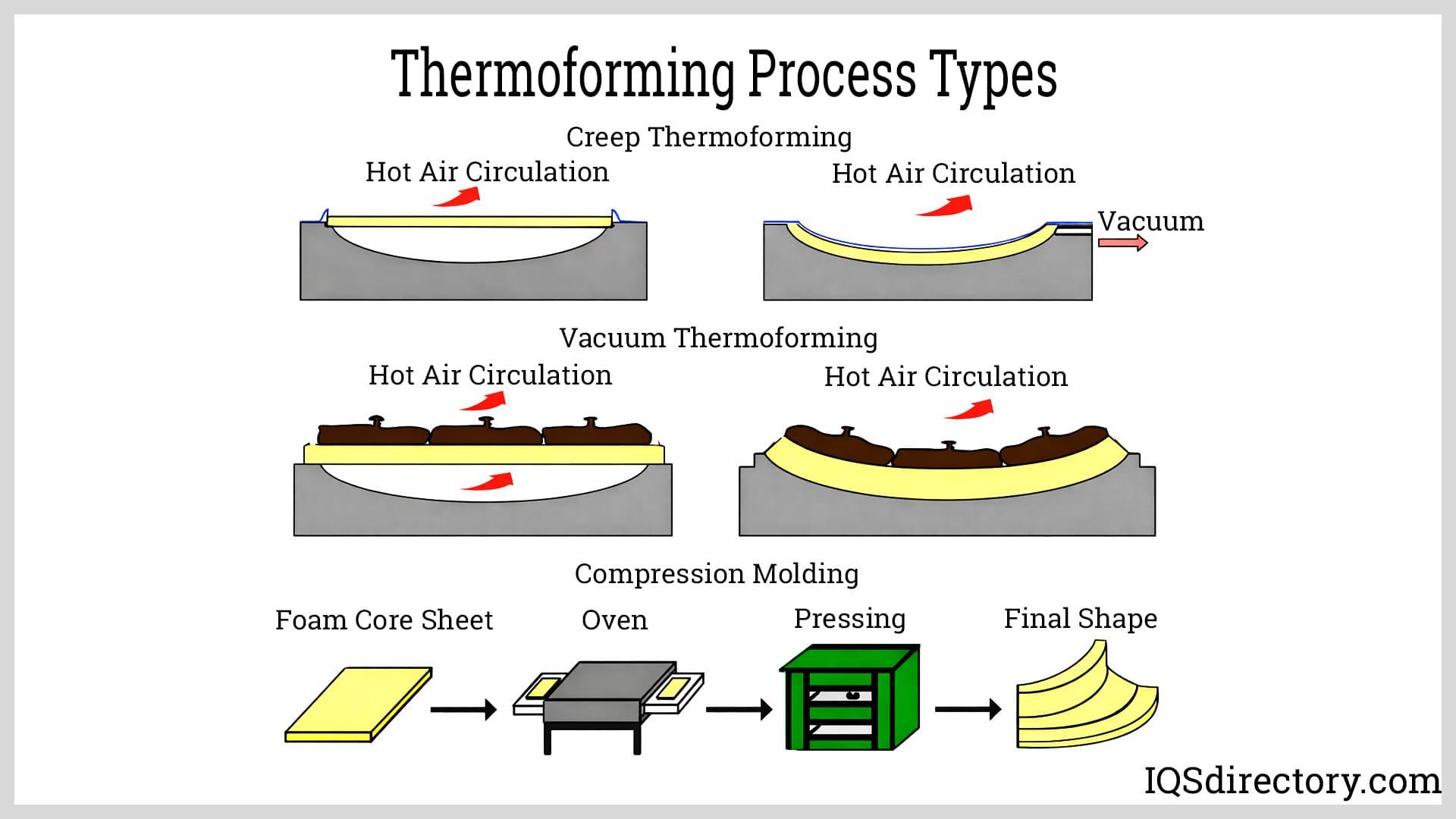

To create products such as these, fabricators manipulate crosslink foam via thermoforming and compression molding. These methods are accurate, reliable and allow for customization. Fabricators sell crosslink foam products in a wide variety of shapes, sizes, thicknesses, densities and colors. On products like yoga mats, fabricators can even print patterns and designs. They can also design them to meet a wide range of standard requirements related to a wide range of specifications, such as: Mil-specs (military), FDA (food and medicine), EPA (environment) or UL (safety).

To learn if crosslink foam is right for your project, reach out to one of the many excellent crosslink foam fabricators we have listed on this page. They will be able to guide you in the right direction and make sure you make the best decisions for your application. Good luck!

Die Cutting

Die Cutting Foam Fab

Foam Fab Gaskets

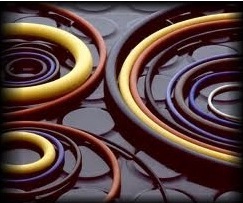

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services