Thermoplastic foam products are a staple in our world, and there are many different ways to form them, depending on your application. Compression molding is one such process; it is used to make 3D shapes and contoured 3D shapes. Read More…

Compression molding is a process Flextech utilizes for the manufacturing of three-dimensional molded foam and foam composite parts. It is an ideal process for making parts that have intricate features, require very defined part geometry, have varying wall thicknesses or need to be held to critical dimensional tolerances. Flextech utilizes our compression molding processes to manufacture parts...

More Compression Molding Foam Companies

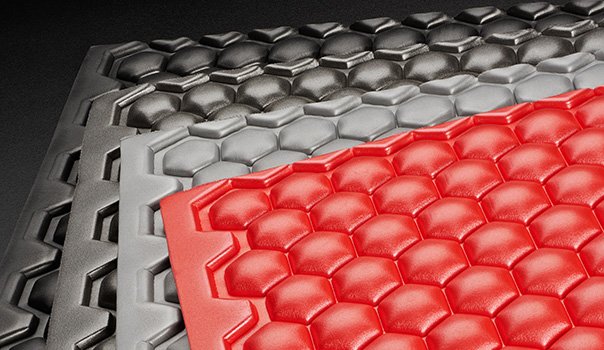

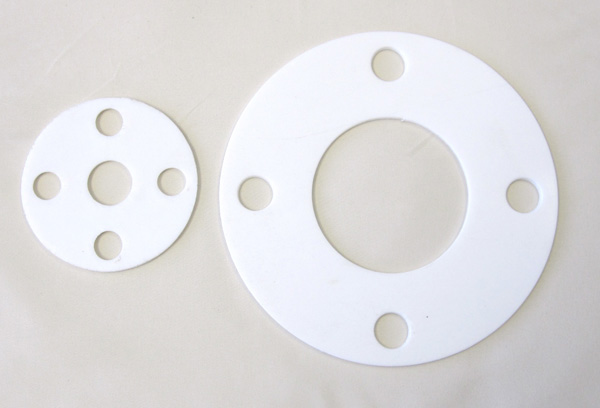

Some of those products created via foam compression molding include: helmet padding, wrist supports, orthotics, case inserts, 3D gaskets, backpack parts and seals. The process and the products it produces are popular in industries such as: healthcare and rehabilitation, sports and recreation, military and defense, consumer, electronics, aerospace, transportation, packaging and industrial fabricating.

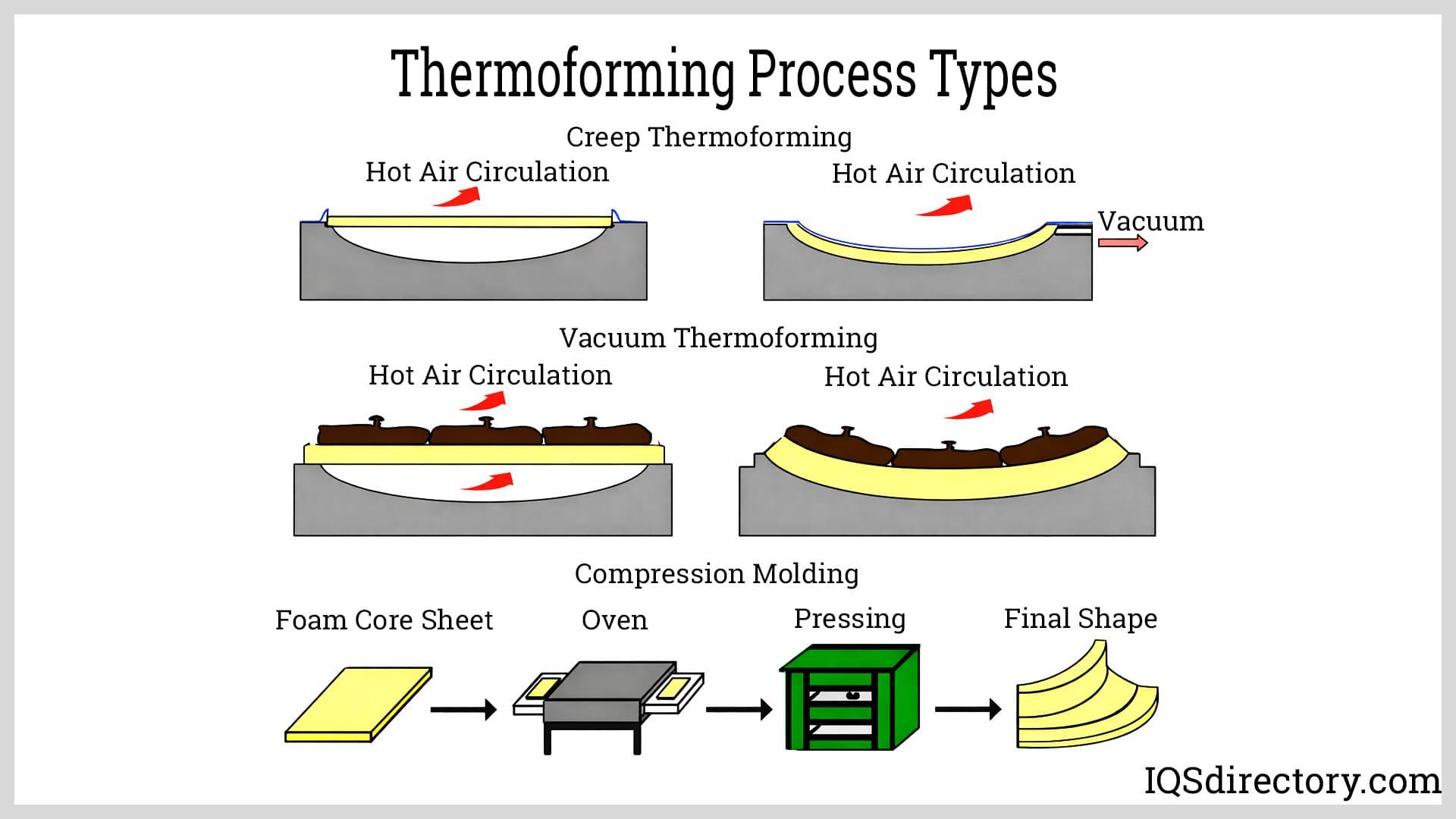

During this fabrication process, fabricators take a foam of some sort and either place it in a temperature controlled cavity or heat it in an oven beforehand. Either way, once it is inside the mold, hydraulic press then closes it and applies pressures. Said pressure forces the foam to make contact with every bit of the mold surface. After it takes on the mold’s shape, it is allowed to cool. Then, fabricators open the mold back up and take the new molded part out. Fabricators can mold both open celled and closed cell foams.

Some of the materials used most often when compression molding foam include: PVC foams, cross-linked polyethylene foams, open cell urethane foams and ethyl vinyl acetate (EVA) foams. Composite foams are also available; these feature other materials, like: pressure-sensitive adhesives, polyolefin films, woven fabrics and medical grade coatings. Compression molded foams such as these offer a variety of advantages, such as (depending on their composition): insulation, impact resistance, vibration resistance, flame retardance, chemical resistance, tensile strength and sterility. Some foams can even be designed to meet FDA or Mil-Spec standards.

Compression molding foam is great way to go for many reasons. First, because the process is so simple, it is relatively inexpensive. In addition, it does not require much, if any, secondary tooling. That’s because it does not produce waste like sprues or runners. Third, compression molding foam is suitable for very large parts that require intricacies. To learn more about compression molding foam, and if this process is right for you, reach out to a trusted parts fabricator. Use the company names and profiles we’ve provided on this page to guide you.

Die Cutting

Die Cutting Foam Fab

Foam Fab Gaskets

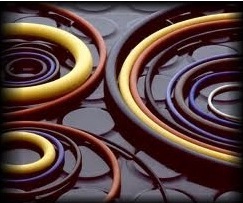

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services